Preventing condensation: During the operation of wind power equipment, temperature fluctuations may cause water vapor condensation. Rotary dehumidifiers can timely remove moisture, avoiding condensation damage to the equipment.

Ensuring electrical performance: Moisture affects the performance and reliability of electrical components. Rotary dehumidifiers help maintain a good electrical environment.

Extending maintenance cycles: By controlling humidity, the risk of equipment corrosion due to moisture is reduced, thereby extending maintenance and overhaul intervals.

Improving operational efficiency: A good humidity environment is conducive to the efficient operation of wind power systems.

The principle of wind power generation is to make use of the wind to drive the rotation of the windmill blades, and increase the rotation speed through the speed booster, drying the generator to generate electricity. Based on current windmill technology, a breeze speed (wind scale of breeze) of about 3 m/s can start the power generation. Wind power is booming in the world because it has no problems on fuel, and produces no radiation or air pollution. Wind power uses natural energy. Compared with thermal power, nuclear power, etc., it is more green and environmentally friendly. Wind power is very popular in northern European countries such as Denmark.

The principle of wind power generation is to make use of the wind to drive the rotation of the windmill blades, and increase the rotation speed through the speed booster, drying the generator to generate electricity. Based on current windmill technology, a breeze speed (wind scale of breeze) of about 3 m/s can start the power generation. Wind power is booming in the world because it has no problems on fuel, and produces no radiation or air pollution. Wind power uses natural energy. Compared with thermal power, nuclear power, etc., it is more green and environmentally friendly. Wind power is very popular in northern European countries such as Denmark.

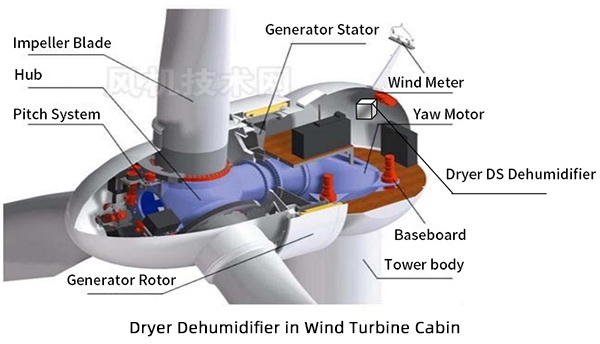

The wind turbine is located in the outdoor harsh environment, so the main feature of wind turbine dehumidifier is: large temperature range (-15~55°C). Even in a low-temperature environment with rain and snow, the dehumidifier must ensure effective work; for example, when the outside temperature is below 10°C (such as the wind power generation environment in winter or rainy days, on rivers and at coastlines), the relative humidity in the generator cabin must be ensured below 40%, which is difficult to achieve for froze dehumidifier.

The wind turbine is located in the outdoor harsh environment, so the main feature of wind turbine dehumidifier is: large temperature range (-15~55°C). Even in a low-temperature environment with rain and snow, the dehumidifier must ensure effective work; for example, when the outside temperature is below 10°C (such as the wind power generation environment in winter or rainy days, on rivers and at coastlines), the relative humidity in the generator cabin must be ensured below 40%, which is difficult to achieve for froze dehumidifier.