Rotary dehumidifiers are crucial for ice rinks. Firstly, they can effectively control the humidity of the ice rink, maintaining the good condition of the ice surface, preventing it from becoming soft or uneven due to high humidity, thus ensuring the safety and comfort of skaters. Secondly, suitable humidity also helps reduce ice surface wear and damage, thus extending the rink's lifespan. Additionally, it improves the air quality in the ice rink, eliminates fog and condensation, and keeps the air fresh, enhancing the overall environment quality of the ice rink.

Mechanism: wet air is cooled below zero degree so its humidity comes out of air and turns into condensed water.Since the temperature ranges from 20-23 degree and the humi dity is below 65%,a relatively dry state,for the air passing through the venue,the power cons umption is much higher than absorption based dehumidifier.As a result,such application is less used in other countries.

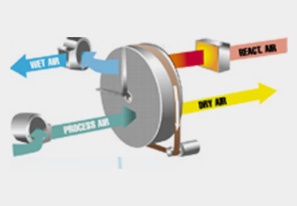

Desiccant rotor was first used for ice-skating places in Europe thirty years ago.Rotor ab sorbs the water molecules in processing sector and releases them in regeneration sector with higher temperature.In such a way,the water has been removed from the wet air and becom esdry.This method has been useduntil now.

Desiccant rotor was first used for ice-skating places in Europe thirty years ago.Rotor ab sorbs the water molecules in processing sector and releases them in regeneration sector with higher temperature.In such a way,the water has been removed from the wet air and becom esdry.This method has been useduntil now.

After six years of research and development by Dryer,a new product,low temperature regenerative rotor,has been launched.At present,it is the world's first hydrophobic material based rotor which can utilize the low level waste heat to regenerate,such as heat of condens ation from the coolers.

Compared with traditional desiccantrotor,low temperature regenerative rotor reduces energy consumption in regeneration process and hence the running cost after the commissio ning.Dryer low temperature regeneration dehumidification system is warmly welcome by ice -skating places in Europe.It is a system which hardly consume energy without counting the processing fan.Dryer customers are ready to use the systems full day to guard facilities andi ce surface in the ice-skating places.

With such edge-breaking technology,Dryer winsgreat attention from ice-skating plac es across the border.

Case study: the dehumidification system installed for a 800 square meter indoor ice rink,saves 210 to 220 degree of electric power per hour.The DM2 dehumidifier is immediately accepted by the customer with its excellent cost performance.This is our promise to Dryer customers:one summer to recoup the initial investment!