Since then, the combination of rotor dehumidification and refrigeration had been used as a fixed mode for meat processing environment control, until the new energy-saving technology was introduced to the market.

At the same time, with people's concern about food hygiene issues, related regulations give clear requirements on the ambient temperature and humidity for meat products processing as well as the storage of vegetables and other fresh food, for example: in the meat products processing, the temperature in the pre-cooling rooms of the production needs to be controlled at 0-4°C. When the temperature in the pre-cooling rooms is controlled low, high relative humidity can easily cause the growth of bacteria and microorganisms, thus affecting the quality of food.

At the same time, with people's concern about food hygiene issues, related regulations give clear requirements on the ambient temperature and humidity for meat products processing as well as the storage of vegetables and other fresh food, for example: in the meat products processing, the temperature in the pre-cooling rooms of the production needs to be controlled at 0-4°C. When the temperature in the pre-cooling rooms is controlled low, high relative humidity can easily cause the growth of bacteria and microorganisms, thus affecting the quality of food.

Bacterial microorganisms generate partly at some areas in the production process and partly by the operation of air-conditioning systems. Traditional work principle of air conditioning has fatal flaws: in the process of cooling and dehumidification, it will produce a large amount of condensate, small particles of dust in the air, bacteria, etc. which attach to the evaporator fins with the help of condensate, it is easy to cause bacterial accumulation and reproduction This can lead to repeated contamination by the air going through the air conditioning ventilation system indoor, affecting the quality of processed meat products. But in large-scale processing plants, if the rotor plus air conditioning box is used, and temperature and humidity are handled separately, regeneration of energy consumption is also a non-negligible operating cost.

In 2012, Dryer’s lab realized a major breakthrough in its core adsorption dehumidification technology, applying new non-hydrophilic nanomaterials to the adsorption rotor, and the regeneration temperature of 30-50°C can efficiently evaporate the water left on the surface of the rotor in order to meet the requirements of the dehumidification effect.

Dryer launched the world's first non-hydrophilic, low-temperature regenerative rotary, constant temperature, humidity and aseptic air handling unit in Sweden, which can perform air dehumidification using only the cold waste heat discharged from the refrigeration machine. As meat production plant has a large number of cold storage, low-temperature cold storage, production workshop, refrigeration machines are basically open all year round, condensing waste heat is discharged almost all year round. The application of using the discharged condensing waste heat, and removing the moisture in the air is greatly welcomed by meat production plants.

It not only allows the separate handling of temperature and humidity in the air conditioning unit, essentially eliminating the frosting phenomenon on the evaporator surface (as previously described) and the condensation and bacterial growth on the cooling coils of traditional air conditioning boxes but also provides significant energy savings, which is a huge surprise for the meat production plant users. According to the general experience, it is expected that our customers can recover their initial investment in about 1.5 to 2 years (please check the specific data with Dryer's engineers).

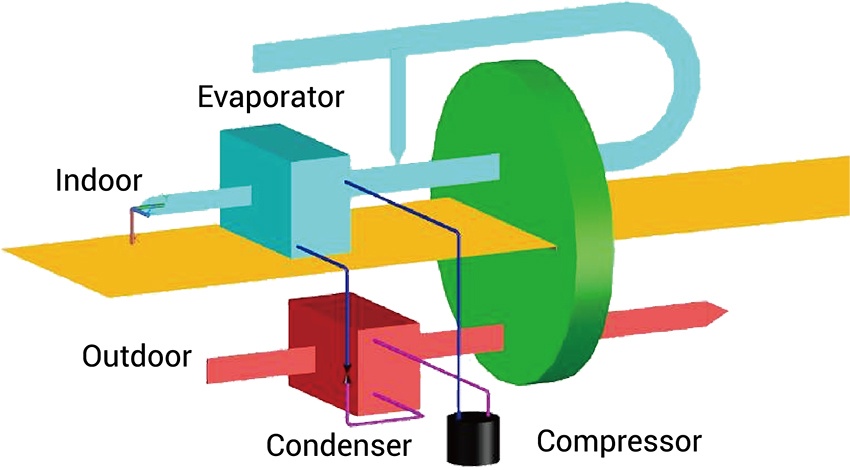

The processed air passes through a humidity control device(low-temperature rotor)which absorbs excess moisture from the air and then sends the dried air to the evaporator. After being cooled, the air is sent into the cold storage. By using an internal circulation system with air return, the cold storage temperature can be maintained while avoiding frost formation on the evaporator surface.

The humidity control device(low-temperature rotor)absorbs moisture from the processed air and then enters the rotor desorption mode. The system uses the heat recovered from the condenser, which would otherwise be discharged into the atmosphere, to desorb the humidity control device. Except for the driving motor, the entire rotor desorption process consumes almost no energy, making it a highly energy-efficient humidity control and frost-free technology for cold storage.