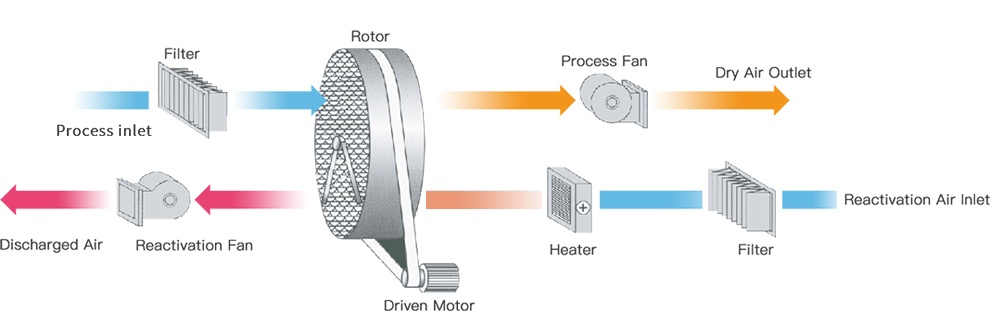

The process air pass through processing area and be dried by desiccant rotor, supply to treated area. The moisture remaining on the desiccant rotor, the saturated rotor turn to reactivation area, absorbed moisture on the rotor will be evaporated by hot air (100C-120) heated by reactivation heater from outside, The wet air will be discharged to outside. The rotor become dry again for next circulation.

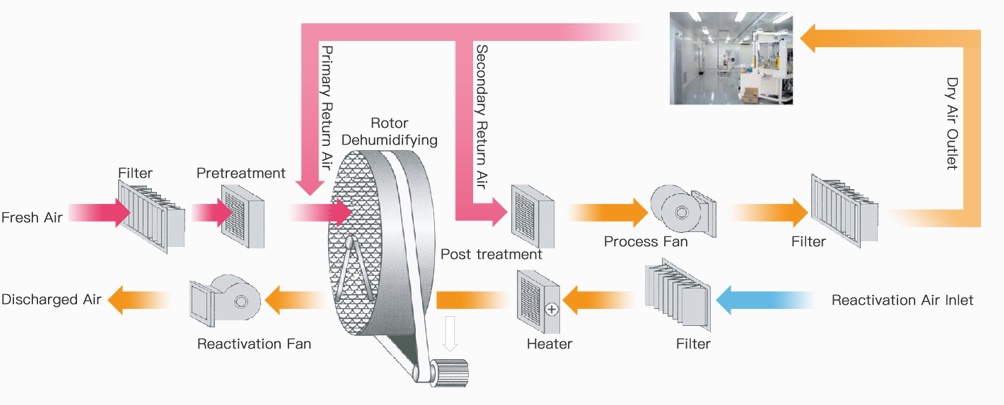

The fresh air passes through the front surface cooling, then is mixed with the primary return air and supplied into the rotor dehumidifying area. The moisture in the air is absorbed by the desiccant agent inside the rotor. The dried air is mixed with the secondary return air, then passes through the steps like rear surface cooling, rear heating, humidifying, etc. to be adjusted to the required temperature, humidity and cleanliness, and is supplied into the workplace (controlled area). The cycle is continuously repeated to meet the requirements of humidity control and temperature control.

The rotor sector in the air treating area absorbs the moisture, becomes saturated, and is automatically rotate to reactivation area for high-temperature reactivation treatment to restore the dehumidifying capability.

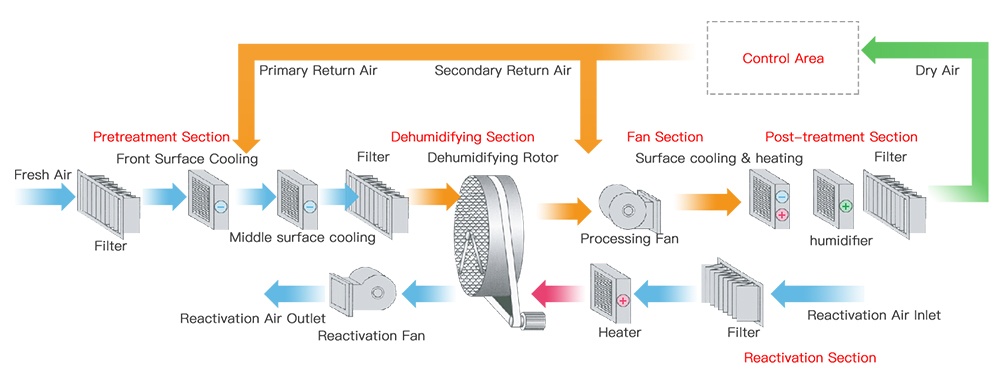

The fresh air passes through the front surface cooling, and then enters the processing area of the rotor; the moisture in the air is absorbed by the desiccant agent inside the rotor, and the dried air is then adjusted to the required temperature by the rear surface cooling (or the rear heating) before being sent into the workplace. The cycle is continuously repeated to meet the requirements of humidity control and temperature control.

The rotor sector in the air treating area absorbs the moisture, becomes saturated, and is automatically rotate to reactivation area for high-temperature reactivation treatment to restore the dehumidifying capability.

Function of each functional section: the rotor is to treat the humidity of the mixed air to the required extreme working humidity, so that the dry air meets the required humidity requirements. The rear surface cooling section or rear heating section is to adjust the temperature of the dry air as required in the workplace.