Case Study

A factory that produces lithium battery materials in Fujian Province needs to operate many air compressors in its production process. Considering energy reuse, it provides each air compressor with a hot water recovery module, and gets hot water at around 55°C as domestic water for its workers. However, the daily volume of the recovered hot water is much more their demands, resulting in energy waste.

AFTER LEARNING SUCH SITUATION, OUR SALES ENGINEER ORGANIZED AN IN-HOUSE PROFESSIONAL TECHNICAL TEAM TO CONDUCT AN ON-SITE INVESTIGATION, AND FOUND THAT:

- All stages of the customer's production process require specific humidity, below 30% at around 26°C; the rotor dehumidifiers in use employ steam or electric regeneration methods.

- The volume of the 55°C hot water recovered by the customer meet the regeneration needs of the dehumidifiers, requiring no additional electric or steam heating.

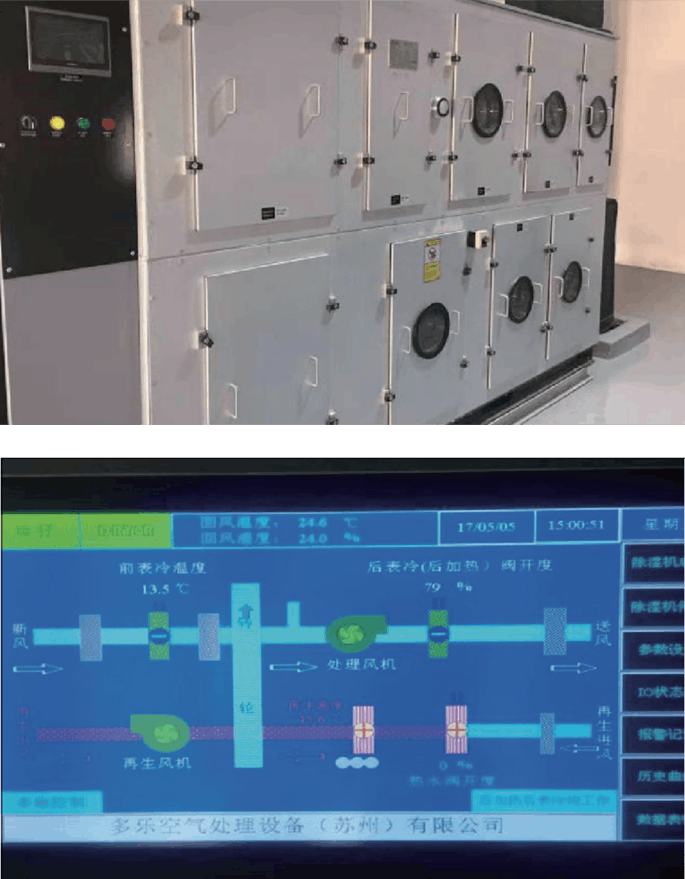

CONSIDERING THE ACTUAL ON-SITE CIRCUMSTANCES, AND ADOPTING THE DRYER

LOW-TEMPERATURE REGENERATION SYSTEM:

The 55°C hot water recovered from the air compressors is used for the dehumidifiers’ regener�ation, with no steam or electric regeneration required. This reduces the cost of regeneration operating which is the most energy consumption of the dehumidifiers, nearly down to zero.

Compared to other earlier workshops, adopting the Dryer Low-temperature Regeneration System allows for the recovery of its initial investment in dehumidification equipment in approximately two years.